Softening veneer -

How to use veneer softener to make your veneer more flexible

Techniques #4

Video that accompanies this article can be found here.

Softening Veneer

When laying up raw wood veneers, they should be flat and flexible for best results. If the veneer is very dry and rippled, it can crack in the pressing process. Also, if it is being applied to a curved surface, like a raised panel door, (Technique #5) it will not flow in the curved area without cracking.

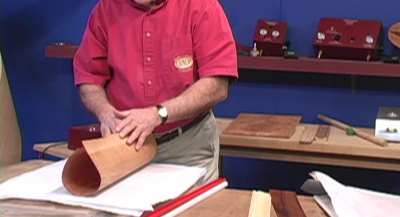

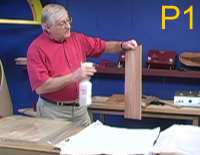

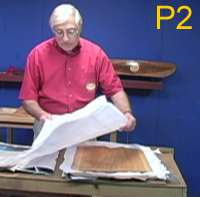

To solve this problem a veneer softener is used. There are formulas for making your own softener or you can purchase commercial softeners like our V-Flex veneer softener which is diluted with an equal amount of water. It is sprayed on both sides of the veneer (P1) then placed in the vacuum bag with plain paper on both sides and a caul on top. Do not use newspaper on top of the veneer as the print could stain the veneer. Brown paper bag or tissue wrapping paper is good(P2). Newspaper can be used on top of the plain paper. When under vacuum, the moisture gets wicked out from under the caul and will evaporate faster when under vacuum. It helps if you add a mesh (plastic window screen, etc.)(P3) in with the paper (not on the veneer) as this helps wick the moisture out faster. You should change the paper several times to speed up the process. Place the assembly (P4) in the vacuum press and apply vacuum.

When your remove it from the vacuum press, check the moisture content to be sure you are back to the correct moisture level, moisture content (MC)(P5). This is an important step and needs to be addressed with a moisture meter. If the MC is too high when it's pressed, the veneer will have expanded. When it's out of the press and fully dried it will want to shrink and this can cause crazing/cracking on the surface. It depends on the wood and the MC as to the extent of the cracking. Also, be sure to measure the center as well as the edges when checking the MC. When in the vacuum press, the edges will dry faster than the center.

Once the veneer has softened and brought to the correct MC, it should stay that way for several days depending on the conditions it will be stored under. It's best to use it within a few days after the softening process has been completed.

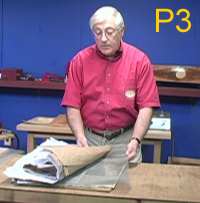

This is a image on how flexible the veneer will be after veneer softener treatment.

1/2 Gallon Veneer Softener makes 1 gallon.

VKS - $36.00

Video that accompanies this article can be found here.

Softening Veneer

When laying up raw wood veneers, they should be flat and flexible for best results. If the veneer is very dry and rippled, it can crack in the pressing process. Also, if it is being applied to a curved surface, like a raised panel door, (Technique #5) it will not flow in the curved area without cracking.

To solve this problem a veneer softener is used. There are formulas for making your own softener or you can purchase commercial softeners like our V-Flex veneer softener which is diluted with an equal amount of water. It is sprayed on both sides of the veneer (P1) then placed in the vacuum bag with plain paper on both sides and a caul on top. Do not use newspaper on top of the veneer as the print could stain the veneer. Brown paper bag or tissue wrapping paper is good(P2). Newspaper can be used on top of the plain paper. When under vacuum, the moisture gets wicked out from under the caul and will evaporate faster when under vacuum. It helps if you add a mesh (plastic window screen, etc.)(P3) in with the paper (not on the veneer) as this helps wick the moisture out faster. You should change the paper several times to speed up the process. Place the assembly (P4) in the vacuum press and apply vacuum.

When your remove it from the vacuum press, check the moisture content to be sure you are back to the correct moisture level, moisture content (MC)(P5). This is an important step and needs to be addressed with a moisture meter. If the MC is too high when it's pressed, the veneer will have expanded. When it's out of the press and fully dried it will want to shrink and this can cause crazing/cracking on the surface. It depends on the wood and the MC as to the extent of the cracking. Also, be sure to measure the center as well as the edges when checking the MC. When in the vacuum press, the edges will dry faster than the center.

Once the veneer has softened and brought to the correct MC, it should stay that way for several days depending on the conditions it will be stored under. It's best to use it within a few days after the softening process has been completed.

This is a image on how flexible the veneer will be after veneer softener treatment.

1/2 Gallon Veneer Softener makes 1 gallon.

VKS - $36.00